| Process

Factory machinery is used to create interlocking pavers. They are made up of cement compounds and aggregate with both fine and coarse grains.

The components go through vibration and pressure courses to create a robust, long-lasting concrete that can be shaped into a variety of patterns.

Color is applied during the vibration and pressure courses to create a more enticing design element.

This is a speedy production technique because the pavers are available for paving right away and don’t require a long curing period.

Materials

cement or concrete

How add colors

Adding masonry coloring to the ready mix.

How it create

Using vibration and pressure of machine.

There are two types of paver blocks

1. Concrete Paving Block

Concrete blocks are mass manufactured to standard sizes. Hence, they can be easily interchanged. A typical concrete block has two surfaces – one is smooth, and the other is a rough surface. The concrete paving blocks are most suitable for heavy-duty applications, able to support substantial loads and resist shearing and braking forces. The concrete blocks come in various colors. The colors typically come from metallic oxides. However, there is a possibility of these colors to fade away. Hence one needs to be very careful while choosing the color of the block. Concrete paving blocks are the most preferred choice for laying of pavements, driveways, etc.

2. Clay Paving Blocks

Clay paving blocks are also called bricks or cobbles. These blocks are generally available as typical, rectangular brick-shaped. Although custom shapes can be made for specific projects. Unlike the concrete paving blocks, either side of clay paving blocks can be used. So both sides are interchangeable. Clay blocks are available in natural color only; hence the possibility of color fading is not there in these blocks. These blocks are mostly used for walls or pillars.

Shapes and Classification of Paver Blocks

There are four generic shapes of paver blocks corresponding to the four types of blocks:

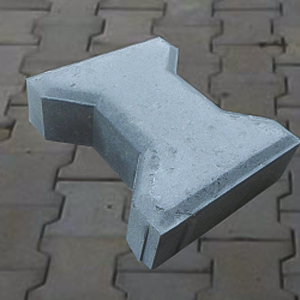

- Type A: Paver blocks with plain vertical faces, which do not interlock into each other when paved in any pattern,

- Type B: Paver blocks with alternating plain and curved/corrugated vertical faces, which lock into each other along the curve/corrugated faces, when paved in any pattern,

- Type C: Paver blocks having all faces curved or corrugated, which lock into each other along with all the vertical faces when paved in any pattern and

- Type D: ‘L’ and ‘X’ shaped paver blocks that have all faces curved or corrugated and which lock into each other along with all the vertical faces when paved in any pattern.

- Advantages of Paver Blocks

- Paver blocks do not need special maintenance as compared to concrete or asphalt surfaces. A simple water washing can help keep the blocks clean and bright.

- Paver blocks are very durable, and if they are adequately interlocked, they can easily last for about 20 years. Paver blocks can withstand hefty vehicular load as well.

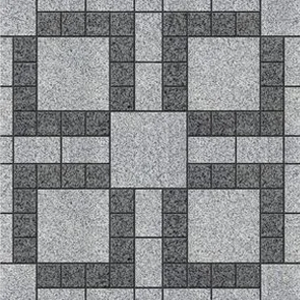

- Paver blocks are available in different shapes and colors, making it very versatile. These blocks can be used at residential as well as commercial premises.

- Paver blocks are slip-resistant and skid resistant.

- Paver blocks can be used in any weather conditions.

- These paver blocks are very easy to install and do not need any special equipment for its installation.

- The most important advantage of paver blocks is that they can be easily replaced. If one of the blocks gets damaged, it can be easily removed and replaced with another one.

With all these advantages, paver blocks are the most sort after solution for exterior pavement or driveways. These paver blocks not only make the exterior pathways look clean and neat but are also safe for walking on. Paver blocks are a definite solution for a low maintenance pathway.

How interlocking pavers are laid ?

1. Lay Bedding Sand

A bed of sand is necessary to provide final leveling properties and help secure the pavers in place. Use clean, sharp concrete sand 1-inch deep. Allow for 1 cubic yard of sand per 300 square feet of project area.

2. Install Edge Restraint

Install a stable edge restraint to eliminate any lateral movement of the pavers and sand bedding. Examples of edge restraints include an existing hard edge (such as the side of a house), vinyl molded restraints or concrete restraints.

3. Lay the Pavers

Place pavers flat on the sand bed, working in a forward motion. Start the process at either a 90-degree corner or within the field by using a pre-set string to guide the straightness of the pavers.

4. Vibrate the Pavers

Once the paver field and borders have been placed, spread a light layer of sand over the pavers and run a vibrating plate compactor over them to begin the interlocking process.

5. Sand the Pavers

Spread dry paver joint or masonry sand over the surface of the paver area approximately ¼ inch deep. Using the vibrating plate compactor, pass over the sanded pavers two or three times to allow sand to fill the voids between the pavers. Sweep remaining sand into voids until they are completely filled.

Types of interlocking pavers.

Wing

Tiles

Cobble

Marble Slabs

Pedesta